Logic with a twist!

Torque is the measure of force that makes an object rotate along its axis. The right torque applied can help you reduce risk, improve productivity, protect you from losses.

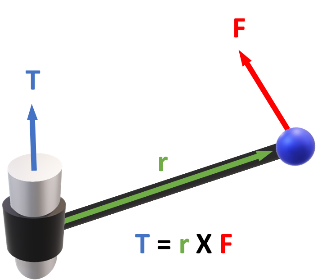

Force causes an object to move along a straight line. Similarly, when we consider an object, which rotates along its own axis, there is a force that causes this rotation.

Torque is the measure of this force, which makes the object rotate along its axis. It can be defined as the rotational equivalent of linear force. In simple words,

it refers to the tendency of an object to turn or twist along its axis when force is applied. It is measured in pound-feet (lb-ft) in the US and Newton Meters (Nm) in the rest of the world.

What role does torque play?

In metal cutting applications, the spindle of machines (VMC, HMC, multi-axis machines, SPMs or turning centres) rotates along its axis and creates a torque. When a metal is cut, the cutting edge produces an equal and opposite force to resist the torque. If the cutting edge or the machine spindle cannot take the designated torque (due to several parameters like depth of cut, high feed value, etc.), the outcome could be disastrous. Another area where torque plays a major role is in fastening. Fastening means assembling two or more parts together with the help of threads. While this looks simple and uncomplicated, one must note that fasteners should not be over tightened or under tightened. Let’s take a look at this example to understand why. On August 20, 2011, the US military lost a surveillance drone in Afghanistan. Subsequent investigation revealed that the crash was due to a loose screw. Because of the under tightened screw, an electric cable got disconnected from the onboard computer, the drone lost contact with the base and crashed. A loose screw cost the US military USD 73 million.

What role does torque play?

In metal cutting applications, the spindle of machines (VMC, HMC, multi-axis machines, SPMs or turning centres) rotates along its axis and creates a torque. When a metal is cut, the cutting edge produces an equal and opposite force to resist the torque. If the cutting edge or the machine spindle cannot take the designated torque (due to several parameters like depth of cut, high feed value, etc.), the outcome could be disastrous. Another area where torque plays a major role is in fastening. Fastening means assembling two or more parts together with the help of threads. While this looks simple and uncomplicated, one must note that fasteners should not be over tightened or under tightened. Let’s take a look at this example to understand why. On August 20, 2011, the US military lost a surveillance drone in Afghanistan. Subsequent investigation revealed that the crash was due to a loose screw. Because of the under tightened screw, an electric cable got disconnected from the onboard computer, the drone lost contact with the base and crashed. A loose screw cost the US military USD 73 million.

It is quite natural to conclude that it is better to over tighten the fastener rather than under tighten it. This belief is prevalent while tightening the inserts of cutting tools. The operator tends to think that tighter screws imply better safety. So, he uses the screwdriver, which comes along with tool, and over tightens the insert screws.

In such a scenario, if you are lucky, you will end up with only damaged screwheads and increased screw consumption. But if you are not lucky, the over tightened screws can shear off, thereby releasing the inserts from the cutter while rotating. This will cause costly damage to the workpiece

fixture, and machine. Moreover, flying inserts could injure the operator or even bystanders. Injury could probably be prevented in modern machines, which are provided with bullet-proof doors, but spare a thought for the machine spindle!

Why do over-tightened fasteners shear off?

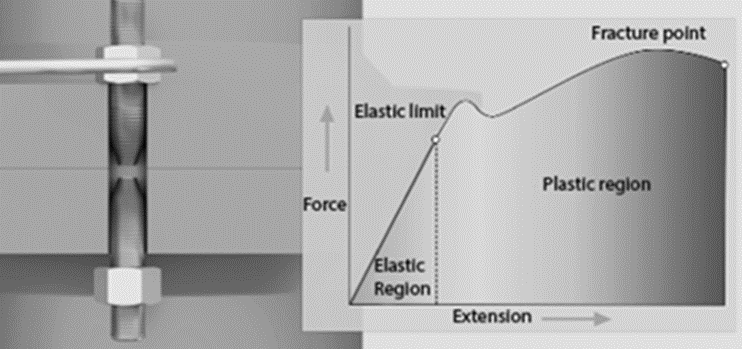

While tightening, the torque applied creates tension on fasteners. This tension will lead to the generation of tensile forces, which will force the fastener to stretch. If this tendency to stretch is higher than the capability of the fastener, it will shear off in the assembled condition. Young’s Modulus of Elasticity defines this phenomenon as, “a solid material will undergo elastic deformation when a load is applied to it”.

Why do over-tightened fasteners shear off?

While tightening, the torque applied creates tension on fasteners. This tension will lead to the generation of tensile forces, which will force the fastener to stretch. If this tendency to stretch is higher than the capability of the fastener, it will shear off in the assembled condition. Young’s Modulus of Elasticity defines this phenomenon as, “a solid material will undergo elastic deformation when a load is applied to it”.

A fastener is not just something that simply holds parts together. Fasteners have a complex combination of mechanical properties and design features, which enable them to function properly and safely. The type of head and thread, dimensions, material, and tightening requirements are to be carefully identified when deciding on the type of fastener required for that assembly. Determining how much torque is needed depends on many factors, but, most importantly, on material properties of the fastener and purpose of fastening. Fastening is not simple and uncomplicated.

Keep in mind…

An under-tightened fastener will not be able to provide the required clamping force and an over tightened fastener will break. Correct tightening is crucial for the safety and performance of an assembled part. Therefore, applying the correct torque is of utmost importance. Torque tools ensure that the amount of torque applied is correct and safe. DR. TORQUE administers remedial solutions for right fastening with right torque tool.

Keep in mind…

An under-tightened fastener will not be able to provide the required clamping force and an over tightened fastener will break. Correct tightening is crucial for the safety and performance of an assembled part. Therefore, applying the correct torque is of utmost importance. Torque tools ensure that the amount of torque applied is correct and safe. DR. TORQUE administers remedial solutions for right fastening with right torque tool.